The report provides the reader with a global market present scenario, market analysis, trends, Global shares, and key manufacturers thriving in 2 shot injection molding industry. New strategies implemented by 2 shot injection molding companies based on sudden COVID19 outbreak are a highlight of this report. There are various methods of molding that manufacturers use when producing plastic or silicone products on large scale owing to an explicit increase in demand for plastic globally. One of those molding methods is the 2shot injection molding method.

What is 2 shot injection molding procedure?

Two-shot injection molding also referred to as dual shot injection molding or twin injection molding is the method of manufacturing complex detailed parts by the amalgamation of two different materials having similar malleable properties. One material is injected into the mold forming a portion of the product. The second material is then injected right after the first material has settled.

These two resins are injected one after the other into the mold, depending upon the design pattern to form a molecular bond producing a multi resin high-end product which is then ejected once cooled. Generally, in 2 shot injection molding, soft-touch materials are molded in combination with strong substrates to improve the design of the product ergonomically and aesthetically.

Materials ranging from acetal, HDPE/LDPE, acrylic, ABS, polyvinyl chloride, thermoplastic, PEEK, Polystyrene, polycarbonate, nylon, polypropylene, PET, and Copolymer polypropylene can be molded using a 2 shot injection molding machine.

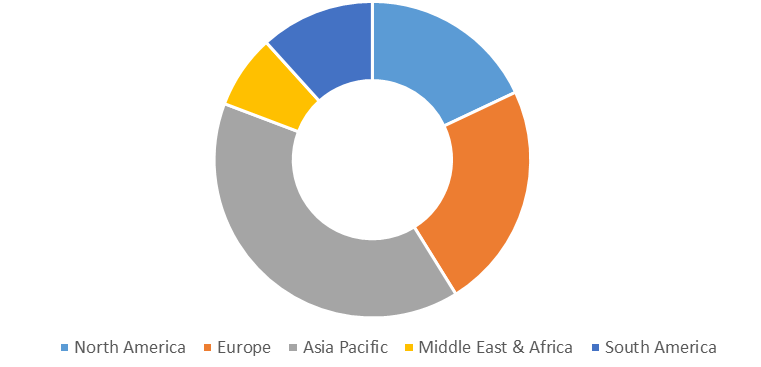

2 Shot Injection Molding Market Value Share Analysis, by Geography (2021)

The report titled “2 Shot Injection Molding Market - Global Market Share, Trends, Analysis and Forecasts, 2022-2032” wherein 2020 is historic period, 2021 is the base year, and 2022 to 2032 is forecast period. Additionally, the study takes into consideration the competitive landscape, wherein the report would provide company overview and market outlook for leading players in the global 2 shot injection molding Market. Furthermore, the report would reflect the key developments, global & regional sales network, business strategies, research & development activities, employee strength, and key executive, for all the major players operating in the market.

Driving factors for 2shot injection molding market

Massive Consumption of plastic products globally is the key driving factor in the growth of the 2shot injection molding market. Covid19 outburst worldwide called for the immediate large-scale production of healthcare and bio-medical equipment in all shapes and sizes. Manufacturing Personal protective equipment (PPE) kits during COVID19 spread are the need of the hour. Although, small but crucial items like valves for ventilators, syringes, and plastic spray bottles are in massive demand all over the globe at present.

The research estimated the value of the market as USD 15.1billion by 2030. Projected to rise by CAGR of approximately 5% for the next 5 to 10 years. China manufactures are the leaders of 2 shot injection molds and are estimated to grow at 8.4% CAGR until 2030.

Trends and analysis

Polypropylene was seen dominating 2 shot molding when considering based on product type segment. Polypropylene held the major shares in 2 shot molding market during 2020 in China as well as globally.

Following polypropylene is silicone. Surfacing as a highly promising segment.

The reason being its thermo-mechanical properties and ease in processing. Versatile uses of silicone in medical, automotive electrical, and electronics industry and healthcare industry being the reason.

The development of polymer materials increased following the dip in prices of crude oil and increasing global demand for polymer products. The rising medical segment held major shares in 2 shot molding market during 2020. The estimated increment in its share is 2.8% by 2030. Resulting in stable and long-term revenue gains from the medical and health care segment according to trend analysis.

Forecast regarding growth in 2 shot molding market

Highly precise molding of complicated parts in repeated cycles on large scale is possible due to 2 shot injection molding. Adhering to this emergency mass production of resin and plastic items 2shot injection molding market is forecasted to soar high between 2020- 2030. Studies show that erratic disruption in the global economy caused due to covid19 outspread is likely to decrease shares of the industrial segment by 1.6% by 2031.

Asia-Pacific region to dominate the market

Major markets that are supposed to be positively affected due to growth in the 2 shot injection molding market are the Packaging industry, Beverage industry, pharmaceutical industry, biomedical industry, Printing, and telecommunication industry during the year 2020 - 2030.

The 2 shot injection molding Market is segmented on the basis, Type, Application and geography. Based on Type, the market is segmented into Polypropylene, Polycarbonate, Acrylonitrile Butadiene Styrene (ABS), Polystyrene and Other Plastics. Based on Application, market is segmented into Medical Automotive, Consumer Goods, Electrical & Electronics, Industrial, and Packaging. Based on geography, the market is segmented into North America, Europe, Asia Pacific and Rest of the world.

The research provides in-depth analysis of prominent players holding majority share of the global market with a focus on all operating business segment and would identify the segment of the company focusing on 2 shot injection molding Market. Further, market share of prominent companies in the global 2 shot injection molding Market would also be estimated. The study takes into consideration the key competitive information such as business strategy, product portfolio, key development, swot analysis, and research and development focus of all the 2 shot injection molding companies. The global 2 shot injection molding market study would take into consideration the participants engaged throughout the supply chain and value chain of the market, along with their contribution. Product portfolio would focus on all the products under the 2-shot injection molding market segment of the company. Similarly, the recent development section would focus on the latest developments of company such as strategic alliances and partnerships, merger and acquisition, new product launched and geographic expansion in the global 2 shot injection molding market.

Major competitor companies in 2 shot injection molding industry across the globe are Gemini Group, Inc, Rogan Corporation, Nylon craft, Inc, Paragon Rapid Technologies Ltd, Season Group International Co, Ltd, Midstate Mold and Engineering, Girard Rubber Corporation, SIMTEC Silicone Parts, CMG plastics, EVCO plastics, Yomura Technologies, Crclo Technologies.

Segmentation of 2 shot injection molding market are:

By type

By Applications

By Geography

The 2 shot Injection molding are largely used in the Medical Automotive, Consumer Goods, Electrical & Electronics, Industrial, and Packaging.

The base year considered in 2 shot Injection molding market report is 2021.

Major players operating in the global 2 shot Injection molding market include Gemini Group, Inc, Rogan Corporation, Nylon craft, Inc, Paragon Rapid Technologies Ltd, Season Group International Co, Ltd, Midstate Mold and Engineering, Girard Rubber Corporation, SIMTEC Silicone Parts, CMG plastics, EVCO plastics, Yomura Technologies, Crclo Technologies.

Copyright © 2025 Same Page Management Consulting Pvt. Ltd. (insightSLICE) | All Rights Reserved