The global UV curable coatings market size was estimated to be US$ 6.25 billion in 2020 and is expected to reach US$ 19.5 billion by 2031 at a CAGR of 10.9%.

Ultraviolet curing alludes to a photochemical cycle where extreme intensity ultraviolet light is utilized to right away fix or "dry" inks, coatings, or adhesives.

The ultraviolet frequencies generally appropriate for curing inks lie somewhere in the range of 200 and 400 nanometers. There are a few sorts of light reasonable for producing these frequencies, the fundamental ones being high-pressure mercury-arc lights, electrodeless lights, and medium-pressure mercury-curve lights. This setup is more gainful over utilizing customary curing and drying post dying techniques since it has lesser chances of defects and blunders, speed transportation along with lesser chances of any airborne particles settling upon the item is reduced.

Sorts of ultraviolet lights frequently utilized in the UV curing measure are as follows. Mercury Fume Light (H Type). This light yields light in the reach somewhere in the range of 220 and 320 nanometers. It's incredible for clear coatings and thinner layers of ink because of the subsequent real shine and further developed sturdiness of uncovered finishes and surface fixes.

Next is, Mercury Fume Light with Iron Added substance (D Sort). Adding iron changes, the yield of a mercury fume light, going from 350 to 400 nm. This kind of light functions admirably with densely pigmented inks and cements, just as with thicker layers of clear materials. Coming next is, Mercury Fume Light with Gallium Added substance (V Sort).

Along with gallium, then again, changes this present light's yield to 400 to 450 nm. It's best when utilized for curing white pigmented inks and coatings that contain titanium dioxide. Next in the line is, Fluorescent Lights, Fluorescent lights are commonly utilized when a producer wishes to stay away from the thermal heat emitted by a mercury fume light, or when a thing being relieved should be encircled by light.

Also, fluorescent lights can deliver ultraviolet light anyplace inside the UVA/UVB range and require less energy than mercury lights. The disadvantage is that fluorescent lights are not exactly as proficient as mercury fume lights at creating ultraviolet light, which can prompt more slow curing or the need to utilize various fluorescent lights on one thing. Following next is LEDs.

LEDs are incredibly particular lights that emanate ultraviolet light inside an exceptionally restricted range that is commonly 10 nanometers. Driven lights, while incredibly costly, can last up to multiple times longer than other UV lights and require no startup or cool down period.

In 2019, Duracote redesigned from fluorescent lights to LEDs. This expanded our efficiencies by decreasing the measure of energy utilized, permitted us to speed up and better control our degree of fix across the web. UV curable coatings are likewise being used out of the manufacturing plants and in the field applications that are an immediate consequence of various enhancements in UV relieving gear and innovative changes in the business. In the field relieving, the significant applications are substantial floor covering, wood floor covering, vinyl floor covering, ledges covering, tubs, and covering.

The UV Drove relieving innovation uses in the wood coatings' industry for edge coatings, roller coatings, and computerized printing. UV Drove innovation has diminished energy utilization and essentially decreases work-piece surface temperature. UV curable coatings is utilized for an assortment of properties like polymeric surfaces, including glare decrease, wear or scratch opposition, anti-fogging, microbial obstruction, and synthetic obstruction.

Monomers represent the biggest share of the general market. The monomers are non-combustible materials with low instability and furthermore have sober scent. Monomers by and large can have one until to six UV curable groups, and the quantity of useful groups will decide the properties, the monomer will bring to the UV detailing.

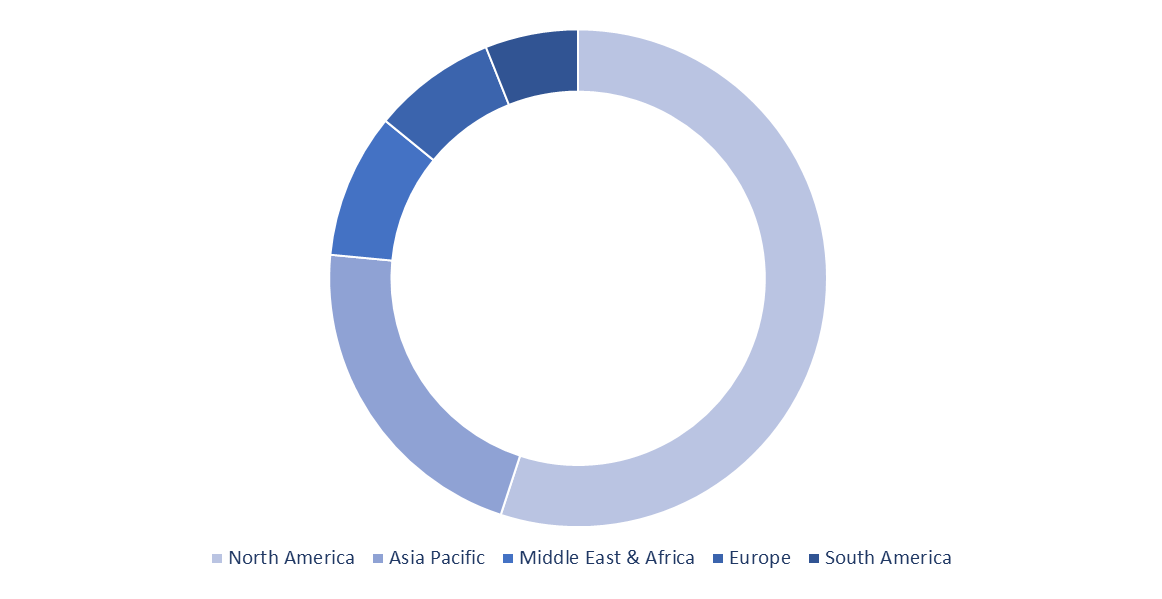

The Asia-Pacific area is postulated to dominate the market, fundamentally because of the popularity of UV-curable coatings in China and Japan. All things considered, consistent industrialization and development in production line units in non-industrial nations offers positive possibilities for expansion to this market during 2023-2032.

Global UV Curable Coatings Market Value Share Analysis, by Geography (2022)

The report titled “Global UV Curable Coatings Market - Global Market Share, Trends, Analysis and Forecasts, 2023-2032”, wherein 2021 is historic period, 2022 is the base year, and 2023 to 2032 is forecast period. Additionally, the study takes into consideration the competitive landscape, wherein the report would provide company overview and market outlook for leading players in the Global UV Curable Coatings Market. Furthermore, the report would reflect the key developments, global & regional sales network, business strategies, research & development activities, employee strength, and key executive, for all the major players operating in the market.

The global UV Curable Coatings market is segmented as Type, Composition, End user, and region. Based on Type, the UV Curable Coatings market is segmented into Wood Coatings, Plastic Coatings, Over Print Varnish, Display Coatings, Conformal Coatings, Paper Coatings, others. Based on Composition, the UV Curable Coatings market is segmented into Oligomers, Monomers, Photoinitiators, PU Dispersions, others. Based on End user, the UV Curable Coatings market is segmented into Industrial Coatings, Electronics, Graphic Arts, other.

Based on geography, the Global UV Curable Coatings Market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. North America is sub-segmented into the United States, Canada, and Rest of North America. Europe is sub-segmented into Germany, United Kingdom, Italy, France, Spain, and Rest of Europe. Asia Pacific is sub-segmented into China, Japan, India, Australia, and Rest of Asia Pacific. Middle East & Africa is sub-segmented into Saudi Arabia, UAE, South Africa, and Rest of Middle East & Africa. South America is sub-segmented into Brazil and Rest of South America.

The research provides in-depth analysis of prominent players holding majority share of the global market with a focus on all operating business segment and would identify the segment of the company focusing on Global UV Curable Coatings Market. Further, market share of prominent companies in the Global UV Curable Coatings Market would also be estimated.

The study takes into consideration the key competitive information such as business strategy, product portfolio, key development, swot analysis, and research and development focus of all the UV Curable Coatings companies. The Global UV Curable Coatings Market study would take into consideration the participants engaged throughout the supply chain and value chain of the market, along with their contribution. Product portfolio would focus on all the products under the UV Curable Coatings business segment of the company. Similarly, the recent development section would focus on the latest developments of company such as strategic alliances and partnerships, merger and acquisition, new product launched and geographic expansion in the Global UV Curable Coatings Market.

The key players of the Global UV Curable Coatings Market are Royal DSM N.V., PPG Industries Inc., Akzo Nobel N.V., BASF SE, and The Sherwin-Williams Company, Axalta Coatings System, Dymax Corporation, Eternal Chemical Co. Ltd., DIC Corporation, and Croda International Plc , and others.

Global UV Curable Coatings Market Key Segments:

Based on Type

Based on Composition

Based on End use

By Region

The global UV Curable Coatings market was worth US$ 6.25 billion in 2020.

The global UV Curable Coatings market is expected to register a CAGR of 10.9% between 2022 and 2032.

Royal DSM N.V., PPG Industries Inc., Akzo Nobel N.V., BASF SE, and The Sherwin-Williams Company are few prominent players active in the market.

Asia-Pacific is the principal contributor to the global UV Curable Coatings market.

The end-use segments in UV Curable Coatings market are Industrial Coatings, Electronics and Graphic Arts.

Copyright © 2025 Same Page Management Consulting Pvt. Ltd. (insightSLICE) | All Rights Reserved